Are you on the quest for the ultimate vaping experience? Look no further than Allo E-Liquid, renowned for its exceptional quality and tantalizing flavors. In this guide, we'll delve into the top three Allo E-Liquid flavors, each offering a unique and satisfying vaping adventure. From sweet and tangy to refreshing and tropical, these flavors are sure to delight your taste buds and elevate your vaping journey.

Allo E-Liquid Salt Blue Raspberry: A Sweet and Tangy Adventure

Experience the delightful fusion of sweetness and tanginess with Allo E-Liquid Salt Blue Raspberry. Dive into a burst of bold blue raspberry flavor with each puff, tantalizing your palate and leaving you craving for more. Crafted with precision and quality ingredients, this e-liquid delivers a perfect balance of sweetness and tanginess, ensuring a satisfying vaping experience every time. Plus, with the added advantage of nicotine salts, you can enjoy smoother throat hits and quicker nicotine absorption, perfect for satisfying your cravings on the go. Whether you're a fan of fruity flavors or simply seeking a refreshing vape, Allo E-Liquid Salt Blue Raspberry is sure to impress.

Indulge in Refreshing Bliss: Allo E-Liquid Salt Blueberry Ice

Escape to a winter wonderland of flavor with Allo E-Liquid Salt Blueberry Ice. This refreshing blend combines the succulent sweetness of blueberries with the invigorating chill of menthol, creating a vaping experience that's both cool and satisfying. With each puff, you'll be greeted by the burst of juicy blueberry flavor, followed by a refreshing icy sensation that leaves your taste buds tingling. Crafted with excellence and attention to detail, Allo E-Liquid Salt Blueberry Ice ensures a smooth vaping experience with every inhale. Whether you're craving a fruity treat or seeking a refreshing vape to beat the heat, this e-liquid is sure to hit the spot.

Zesty Bliss: Exploring Allo E-Liquid Salt Lemon Lime Cranberry

Uncover the perfect balance of tartness and sweetness with Allo E-Liquid Salt Lemon Lime Cranberry. This zesty blend combines the bold flavors Vape Store of cranberries with the tangy zest of lemon and lime, creating a vaping experience that's both refreshing and invigorating. With each puff, you'll be greeted by the tart sweetness of cranberries, followed by a burst of zesty citrus flavor that awakens your senses. Crafted with precision and quality craftsmanship, Allo E-Liquid Salt Lemon Lime Cranberry ensures a satisfying vaping experience with every inhale. Whether you're a fan of tart flavors or simply seeking a refreshing vape, this e-liquid is sure to delight your taste buds.

Conclusion:

In conclusion, Allo E-Liquid offers a range of premium flavors that are sure to satisfy even the most discerning vapers. Whether you're craving the bold sweetness of blue raspberries, the refreshing chill of menthol, or the zesty tang of citrus, Allo E-Liquid has something for everyone. Plus, with the added advantage of nicotine salts, you can enjoy a smoother vaping experience with quicker nicotine absorption. So why wait? Visit Vapery.ca today to explore the full range of Allo E-Liquid flavors and elevate your vaping journey to new heights.

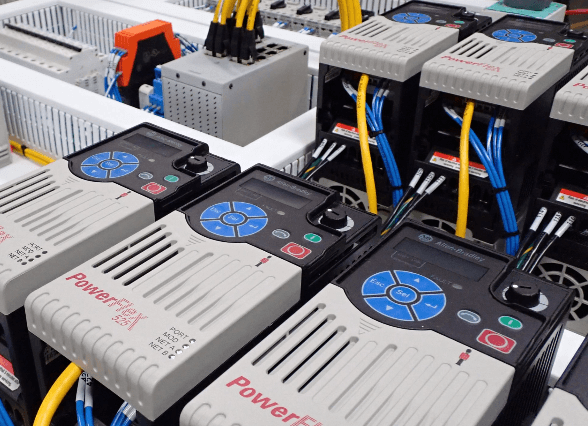

What are control panel systems and why are they critical pieces of plant infrastructure?

Control panel systems, often referred to simply as control panels, are integral components of various industrial and commercial systems. They provide a centralized interface for monitoring, controlling, and managing equipment, processes, and operations across diverse industries such as manufacturing, energy and utilities.

Control panels enable increased efficiency and precision in processes, reducing the need for manual labor and human intervention. They also play a crucial role in ensuring the safety and reliability of industrial equipment and allowing for remote monitoring and control.

Here’s a quick run-down on how control panel systems work:

Control panel functionality

Control panels possess a wide range of functionality, depending on the specific application and industry. They may offer capabilities such as:

> Monitoring and displaying real-time data from sensors, meters, and instruments.

> Control of the operation of machinery, equipment, and processes through switches, buttons, and graphical interfaces.

> Implementation of logic and automation using programmable logic controllers (PLCs), relays, and other control devices.

> Provision of alarms, notifications, and alerts for abnormal conditions or events.

> Configuration and adjustment of system parameters and setpoints.

Integration with other systems and devices through communication protocols such as Modbus, Profibus, Ethernet/IP, and DeviceNet.

Control panel components

Control panels typically consist of several key components, including:

> A Human-Machine Interface (HMI) displays operational data and allows operators to interact with the system through touchscreens, buttons, and indicators.

> Controllers such as PLCs, microcontrollers, or distributed control systems (DCS) execute control algorithms and logic.

> Power distribution components distribute electrical power to equipment and devices, including circuit breakers, fuses, contactors, and terminal blocks.

> Input/Output (I/O) modules connect sensors, actuators, and other field devices to the control system.

> Communication Interfaces in the form of ports and modules connect the control panel to external devices, networks, and systems.

> Protective enclosures or cabinets house the control panel components, providing physical protection from environmental hazards such as dust, moisture, and temperature extremes.

> Electrical wiring, cables, and connectors interconnect components and devices within the control panel.

Control panel design considerations

Designing control panel systems requires careful consideration of various factors to ensure functionality, reliability, and safety. Key design considerations include:

> Electrical Design: Ensuring compliance with electrical codes and standards, proper sizing of components, and adherence to safety guidelines.

> Environmental Conditions: Selecting appropriate enclosure materials and protection ratings to withstand environmental factors such as temperature, humidity, dust, and corrosive substances.

> Ergonomics: Designing user-friendly interfaces and control layouts for intuitive operation and efficient human-machine interaction.

> Scalability and Expandability: Designing modular and flexible control panel systems that can accommodate future expansions, upgrades, and modifications.

> Maintenance and Serviceability: Incorporating features such as access panels, diagnostic tools, and clear labeling to facilitate maintenance, troubleshooting, control system design and repair.

Control panel applications

Control panel systems find applications across a wide range of industries and sectors, including:

> Industrial Automation Solution: Controlling and monitoring manufacturing processes, machinery, and production lines in industries such as automotive, aerospace, food and beverage, and pharmaceuticals.

> Building Automation: Managing HVAC (Heating, Ventilation, and Air Conditioning), lighting, security, and access control system design in commercial buildings, hospitals, schools, and hotels.

> Energy Management: Monitoring and controlling power generation, distribution, and consumption in utilities, renewable energy systems, and smart grids.

>Transportation: Managing signaling, traffic control, and railway systems in transportation infrastructure such as airports, railways, and highways.

Control panel systems: essential for smart manufacturing and digital transformation

At the core of the Automation Solution manufacturing facility control panel systems play a critical role in optimizing operational efficiency, enhancing safety and ensuring compliance is met across diverse industrial and commercial applications.

Modern and connected control panels combined with effective design, integration, and maintenance of control panel systems are essential for achieving your desired smart manufacturing and digital transformation goals of predictive maintenance and real time, contextualized data on a mobile device.

Struggling with old technology? Don’t know where to start?

AutomateIT’s smart manufacturing consultants Control panel systems are able to meet you where you are at along your journey toward smart factory. Let’s get started!

417.429.4320

[email protected]

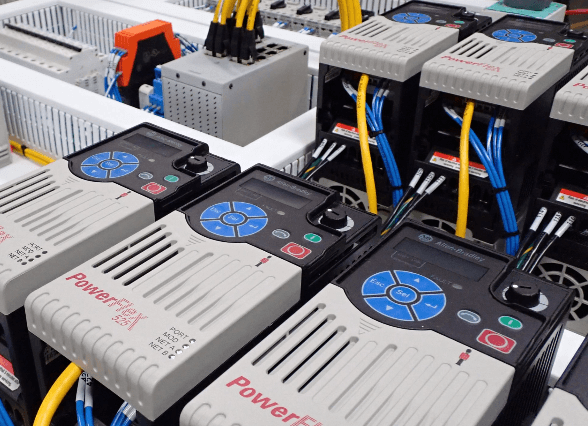

What are control panel systems and why are they critical pieces of plant infrastructure?

Control panel systems, often referred to simply as control panels, are integral components of various industrial and commercial systems. They provide a centralized interface for monitoring, controlling, and managing equipment, processes, and operations across diverse industries such as manufacturing, energy and utilities.

Control panels enable increased efficiency and precision in processes, reducing the need for manual labor and human intervention. They also play a crucial role in ensuring the safety and reliability of industrial equipment and allowing for remote monitoring and control.

Here’s a quick run-down on how control panel systems work:

Control panel functionality

Control panels possess a wide range of functionality, depending on the specific application and industry. They may offer capabilities such as:

> Monitoring and displaying real-time data from sensors, meters, and instruments.

> Control of the operation of machinery, equipment, and processes through switches, buttons, and graphical interfaces.

> Implementation of logic and automation using programmable logic controllers (PLCs), relays, and other control devices.

> Provision of alarms, notifications, and alerts for abnormal conditions or events.

> Configuration and adjustment of system parameters and setpoints.

Integration with other systems and devices through communication protocols such as Modbus, Profibus, Ethernet/IP, and DeviceNet.

Control panel components

Control panels typically consist of several key components, including:

> A Human-Machine Interface (HMI) displays operational data and allows operators to interact with the system through touchscreens, buttons, and indicators.

> Controllers such as PLCs, microcontrollers, or distributed control systems (DCS) execute control algorithms and logic.

> Power distribution components distribute electrical power to equipment and devices, including circuit breakers, fuses, contactors, and terminal blocks.

> Input/Output (I/O) modules connect sensors, actuators, and other field devices to the control system.

> Communication Interfaces in the form of ports and modules connect the control panel to external devices, networks, and systems.

> Protective enclosures or cabinets house the control panel components, providing physical protection from environmental hazards such as dust, moisture, and temperature extremes.

> Electrical wiring, cables, and connectors interconnect components and devices within the control panel.

Control panel design considerations

Designing control panel systems requires careful consideration of various factors to ensure functionality, reliability, and safety. Key design considerations include:

> Electrical Design: Ensuring compliance with electrical codes and standards, proper sizing of components, and adherence to safety guidelines.

> Environmental Conditions: Selecting appropriate enclosure materials and protection ratings to withstand environmental factors such as temperature, humidity, dust, and corrosive substances.

> Ergonomics: Designing user-friendly interfaces and control layouts for intuitive operation and efficient human-machine interaction.

> Scalability and Expandability: Designing modular and flexible control panel systems that can accommodate future expansions, upgrades, and modifications.

> Maintenance and Serviceability: Incorporating features such as access panels, diagnostic tools, and clear labeling to facilitate maintenance, troubleshooting, and repair.

Control panel applications

Control panel systems find applications across a wide range of industries and sectors, including:

> Industrial Automation Solution: Controlling and monitoring manufacturing processes, machinery, and production lines in industries such as automotive, aerospace, food and beverage, and pharmaceuticals.

> Building Automation: Managing HVAC (Heating, Ventilation, and Air Conditioning), lighting, security, and access control system design in commercial buildings, hospitals, schools, and hotels.

> Energy Management: Monitoring and controlling power generation, distribution, and consumption in utilities, renewable energy systems, and smart grids.

>Transportation: Managing signaling, traffic control, Automation Solution and railway systems in transportation infrastructure such as airports, railways, and highways.

Control panel systems: essential for smart manufacturing and digital transformation

At the core of the manufacturing facility control panel systems play a critical role in optimizing operational efficiency, enhancing safety and ensuring compliance is met across diverse industrial and commercial applications.

Modern and connected control panels combined with effective design, integration, and maintenance of control panel systems are essential for achieving your desired smart manufacturing control system design and digital transformation goals of predictive maintenance and real time, contextualized data on a mobile device.

Struggling with old technology? Don’t know where to start?

AutomateIT’s smart manufacturing consultants are able to meet you where you smart manufacturing are at along your journey toward smart factory. Let’s get started!

417.429.4320

[email protected]

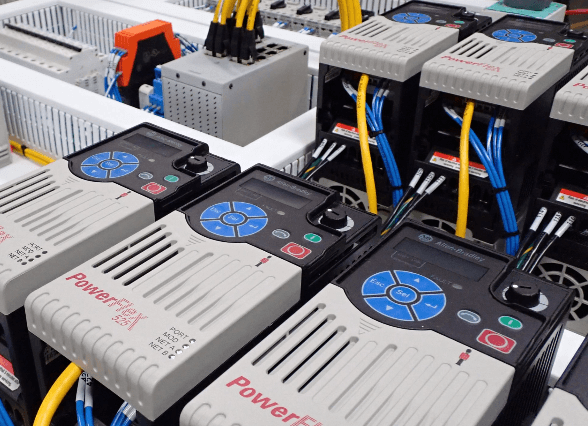

What are control panel systems and why are they critical pieces of plant infrastructure?

Control panel systems, often referred to simply as control panels, are integral components of various industrial and commercial systems. They provide a centralized interface for monitoring, controlling, and managing equipment, processes, and operations across diverse industries such as manufacturing, energy and utilities.

Control panels enable increased efficiency and precision in processes, reducing the need for manual labor and human intervention. They also play a crucial role in ensuring the safety and reliability of industrial equipment and allowing for remote monitoring and control.

Here’s a quick run-down on how control panel systems work:

Control panel functionality

Control panels possess a wide range of functionality, depending on the specific application and industry. They may offer capabilities such as:

> Monitoring and displaying real-time data from sensors, meters, and instruments.

> Control of the operation of machinery, equipment, and processes through switches, buttons, and graphical interfaces.

> Implementation of logic and automation using programmable logic controllers (PLCs), relays, and other control devices.

> Provision of alarms, notifications, and alerts for abnormal conditions or events.

> Configuration and adjustment of system parameters and setpoints.

Integration with other systems and devices through communication protocols such as Modbus, Profibus, Ethernet/IP, and DeviceNet.

Control panel components

Control panels typically consist of several key components, including:

> A Human-Machine Interface (HMI) displays operational data and allows operators to interact with the system through touchscreens, buttons, and indicators.

> Controllers such as PLCs, microcontrollers, or distributed control systems (DCS) execute control algorithms and logic.

> Power distribution components distribute electrical power to equipment and devices, including circuit breakers, fuses, contactors, and terminal blocks.

> Input/Output (I/O) modules connect sensors, actuators, and other field devices to the control system.

> Communication Interfaces in the form of ports and modules connect the control panel to external devices, networks, and systems.

> Protective enclosures or cabinets house the control panel components, providing physical protection from environmental hazards such as dust, moisture, and temperature extremes.

> Electrical wiring, cables, and connectors interconnect components and devices within the control panel.

Control panel design considerations

Designing control panel systems requires careful consideration of various factors to ensure functionality, reliability, and safety. Key design considerations include:

> Electrical Design: Ensuring compliance with electrical codes and standards, proper sizing of components, and adherence to safety guidelines.

> Environmental Conditions: Selecting appropriate enclosure materials and protection ratings to withstand environmental factors such as temperature, humidity, dust, and corrosive substances.

> Ergonomics: Designing user-friendly interfaces and control layouts for intuitive operation and efficient human-machine interaction.

> Scalability and Expandability: Designing modular and flexible control panel systems that can accommodate future expansions, upgrades, and modifications.

> Maintenance and Serviceability: Incorporating features such as access panels, diagnostic tools, and clear labeling to facilitate maintenance, troubleshooting, and repair.

Control panel applications

Control panel systems find applications across a wide range of industries and sectors, including:

> Industrial Automation Solution: Controlling and monitoring manufacturing processes, machinery, and Control panel systems production lines in industries such as automotive, aerospace, food and beverage, and pharmaceuticals.

> Building Automation: Managing HVAC (Heating, Ventilation, and Air Conditioning), lighting, security, and access control system design in commercial buildings, hospitals, schools, and hotels.

> Energy Management: Monitoring and controlling power generation, distribution, and consumption in utilities, renewable energy systems, and smart grids.

>Transportation: Managing signaling, traffic control, and railway systems in transportation infrastructure such as airports, railways, and highways.

Control panel systems: essential for smart manufacturing and digital transformation

At the core of the manufacturing facility control panel systems play a critical role in optimizing operational efficiency, enhancing safety and ensuring compliance is met across diverse industrial and commercial applications.

Modern and connected control panels combined with effective design, integration, and maintenance of control panel systems are essential for achieving your desired smart manufacturing and digital transformation goals of predictive maintenance and real time, contextualized data on a mobile device.

Struggling with old technology? Don’t know where to start?

AutomateIT’s smart manufacturing consultants are able to meet you where you are at along your journey toward smart factory. Let’s get started!

417.429.4320

[email protected]

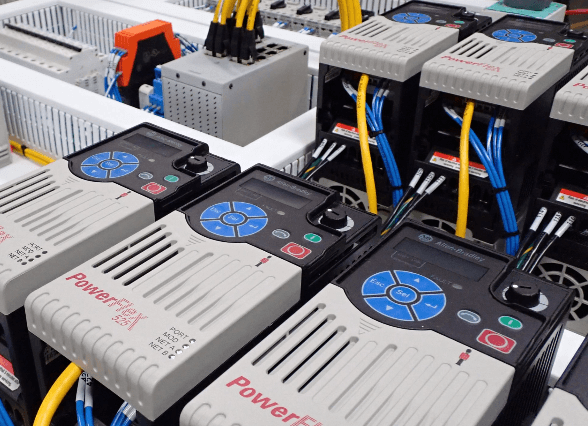

What are control panel systems and why are they critical pieces of plant infrastructure?

Control panel systems, often referred to simply as control panels, are integral components of various industrial and commercial systems. They provide a centralized interface for monitoring, controlling, and managing equipment, processes, and operations across diverse industries such as manufacturing, energy and utilities.

Control panels enable increased efficiency and precision in processes, reducing the need for manual labor and human intervention. They also play a crucial role in ensuring the safety and reliability of industrial equipment and allowing for remote monitoring and control.

Here’s a quick run-down on how control panel systems work:

Control panel functionality

Control panels possess a wide range of functionality, depending on the specific application and industry. They may offer capabilities such as:

> Monitoring and displaying real-time data from sensors, meters, and instruments.

> Control of the operation of machinery, equipment, and processes through switches, buttons, and graphical interfaces.

> Implementation of logic and automation using programmable logic controllers (PLCs), relays, and other control devices.

> Provision of alarms, notifications, and alerts for abnormal conditions or events.

> Configuration and adjustment of system parameters and setpoints.

Integration with other systems and devices through communication protocols such as Modbus, Profibus, Ethernet/IP, and DeviceNet.

Control panel components

Control panels typically consist of several key components, including:

> A Human-Machine Interface (HMI) displays operational data and allows operators to interact with the system through touchscreens, buttons, and indicators.

> Controllers such as PLCs, microcontrollers, or distributed control systems (DCS) execute control algorithms and logic.

> Power distribution components distribute electrical power to equipment and devices, including circuit breakers, fuses, contactors, and terminal blocks.

> Input/Output (I/O) modules connect sensors, actuators, and other field devices to the control system.

> Communication Interfaces in the form of ports and modules connect smart manufacturing the control panel to external devices, networks, and systems.

> Protective enclosures or cabinets house the control panel components, providing physical protection from environmental hazards such as dust, moisture, and temperature extremes.

> Electrical wiring, cables, and connectors interconnect components and devices within the control panel.

Control panel design considerations

Designing control panel systems requires careful consideration of various factors to ensure functionality, reliability, and safety. Key design considerations include:

> Electrical Design: Ensuring compliance with electrical codes and standards, proper sizing of components, and adherence to safety guidelines.

> Environmental Conditions: Selecting appropriate enclosure materials and protection ratings to withstand environmental factors such as temperature, humidity, dust, and corrosive substances.

> Ergonomics: Designing user-friendly interfaces and control layouts for intuitive operation and efficient human-machine interaction.

> Scalability and Expandability: Designing modular and flexible control panel systems that can accommodate future expansions, upgrades, and modifications.

> Maintenance and Serviceability: Incorporating features such as access panels, diagnostic tools, and clear labeling to facilitate maintenance, troubleshooting, and repair.

Control panel applications

Control panel systems find applications across a wide range of industries and sectors, including:

> Industrial Automation Solution: Controlling and monitoring manufacturing processes, machinery, and production lines in industries such as automotive, aerospace, food and beverage, and pharmaceuticals.

> Building Automation: Managing HVAC (Heating, Ventilation, and Air Conditioning), lighting, security, and access control system design in commercial buildings, hospitals, schools, and hotels.

> Energy Management: Monitoring and controlling power generation, distribution, and consumption in utilities, renewable energy systems, and smart grids.

>Transportation: Managing signaling, traffic control, and railway systems in transportation infrastructure such as airports, railways, and highways.

Control panel systems: essential for smart manufacturing and digital transformation

At the core of the manufacturing facility control panel systems play a critical role in optimizing operational efficiency, enhancing safety and ensuring compliance is met across diverse industrial and commercial applications.

Modern and connected control panels combined with effective design, integration, and maintenance of control panel systems are essential for achieving your desired smart manufacturing and digital transformation goals of predictive maintenance and real time, contextualized data on a mobile device.

Struggling with old technology? Don’t know where to start?

AutomateIT’s smart manufacturing consultants are able to meet you where you are at along your journey toward smart factory. Let’s get started!

417.429.4320

[email protected]